-

Lean Manufacturing Operational Excellence Business Excellence

-

Lean Manufacturing Training & Consulting

-

Building World Class Organisations

-

Adding Value in Totality to Business & Family

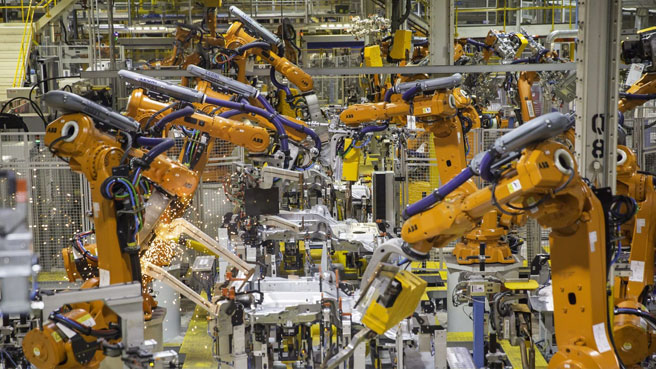

WE ADDVALUE TO ORGANIZATIONS TO ENABLE THEM TO ACHIEVE MANUFACTURING EXCELLENCE.

The purpose of the Family Run Businesses, especially the MSMEs in the manufacturing industry is to continually innovate new products, survive in the fierce global competition, grow, and make profits. However, it has never been that easy. Increased manufacturing costs and reduced Gross Margins result in unhealthy cash flows for the manufacturing sector. Manufacturing needs to focus on Zero Waste methods to improve profitability.

Lean Manufacturing helps industries reduce their manufacturing costs across the value chain and makes them flexible to meet customer requirements. Lean Manufacturing is fundamental for creating Lean Operational Excellence and reducing product costs for better margins. Lean Manufacturing is the only methodology for achieving manufacturing excellence and being competitive in today’s manufacturing sector.

CHALLENGES IN MANUFACTURING:

Industries in the manufacturing sector face several challenges. The most common being:

Achieving Operational Excellence through Lean Manufacturing is the most proven single solution to address all the above challenges in manufacturing.

ADDVALUE is one of the leading Lean Training and Lean Manufacturing Consultancy firms across the globe.

Lean Manufacturing means:

Lean Manufacturing must be applied across the entire value chain to eliminate waste, reduce the costs of goods manufactured, and increase gross profits.

Manufacturing Excellence in Family Businesses means:

Implementing Lean Manufacturing Tools & Lean concepts have several benefits.

Executing Lean Manufacturing is the only way to reduce manufacturing costs and improve turnover, profits, and sustained growth.

Lean Operational Excellence is the perfect methodology for creating organizational effectiveness and efficiency through teamwork.

Materials and Goods need to reach the market, as required, to acquire the shelf space and increase market share.

Information Flow and Material Flow in complete alignment, create Speed to Market using JIT, Supply Chain Management, Lean Distribution, and Logistics, as the prime drivers of excellence.

Lean Pillars and Tools for creating Operational Excellence:

TFM - Total Flow Management, TPM-Total Productive Maintenance, TQM -Total Quality Management, TSM -Total Service Management, THM -Total Human Management

Business decisions need to be quick with a long-term philosophy for growth and profitability. Tools for creating Business Excellence: Vision, Business Modelling, Product Positioning, Strategic Management, Total Financial Management, Total Management by Ratios, etc. Business Growth and profitability is achieved by:

Lean Operational Excellence is the perfect methodology for building efficiency and effectiveness in manufacturing.

Manufactured Goods need to reach the market, as required, to acquire the shelf space, create visibility and increase market share.

Information Flow and Material Flow in complete alignment, create Speed to Market using JIT, Supply Chain Management, Lean Distribution, and Logistics, as the prime drivers of excellence.

Lean Pillars and Tools for Creating Operational Excellence:

TFM - Total Flow Management, TPM-Total Productive Maintenance, TQM -Total Quality Management, TSM -Total Service Management, THM -Total Human Management.

Nilesh R. Arora, is the Founder Partner of AddValue Consulting Inc. (AVCI).

Nilesh Arora is a BTech. (Mech), IIM – Ahmedabad Alumnus, Certified Corporate Director (CCD®), Certified Management Consultant (CMC®), Certified Six Sigma Expert having nearly 25 years of global experience in assisting several achieve Manufacturing Excellence through Lean Manufacturing Training and Consulting and Operational Excellence.

He is a well-known Lean Manufacturing Trainer, Operational Excellence Consultant, and Business Coach and Family Business Advisor.

He is also the pioneer of the Total Lean Management Model (TLM) and 9 Steps to Building World-Class Organizations.

AVCI has been recently awarded “BEST PERFORMING CONSULTING ORGANIZATION AWARD” by the Government of India.

AVCI has been operational in the Asia Pacific – Middle East – Africa region for the past 2 decades.

For more details about Lean Manufacturing Training & Consulting Email : info@avci-lean.com or Call / Whatsapp : +91 9824009792

LEAN Countries

ADDVALUE is the leading Lean Manufacturing Training & Consulting Firm across Asia Pacific-Africa-Middle East

Ask Yourself

If any of the above situations and challenges sound familiar, then you are not alone. All of us look for changes but struggle to achieve them ourselves as we have to move past the current mindsets, habits and beliefs.

How We Help

5S & VISUAL FACTORY

ORGANIZATION STRUCTURING

REDUCING INVENTORY COSTS

IMPROVING EQUIPMENT MAINTENANCE & RELIABILITY

REDUCING MANUFACTURING COSTS

STREAMLINING DISTRIBUTION & LOGISTICS

IMPROVING SALES

ORGANIZATION SCALE UP

IMPROVING GROSS PROFITS