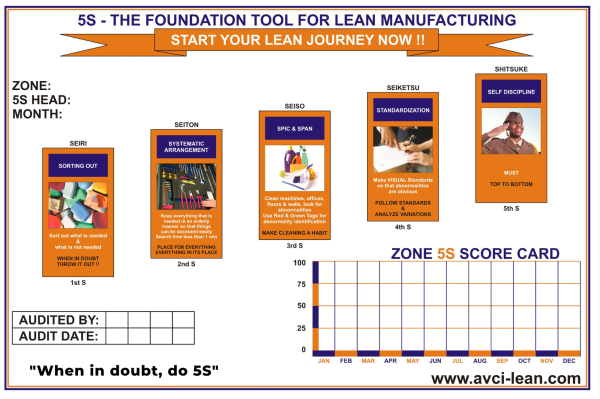

5S is a scientific approach for better housekeeping. To be precise, 5S is an approach for managing the workplace, efficiently with minimal cost and safety.

5S” or "Lean 5S" is a method to promote a safer, cleaner, and better-organized workplace – often a factory, but the 5S method can also be applied to almost any work environment.

A 5S Score board is required to evaluate the effectiveness of each 5S in different areas of the Factory.

Visual Factory is a manufacturing facility, managed through Visual Controls and Visual Displays. In a visual factory, one can get quicker insights into the status of the workplace and the work being done.

Creating a visual factory allows the management to make informed decisions promptly and employees to develop a sense of ownership of the workplace.

For more details about Lean Manufacturing Training & Consulting Email : info@avci-lean.com or Call / Whatsapp : +91 9824009792